鑄鐵平臺DIN876標準設計特點

2017年06月14日

新聞詳情

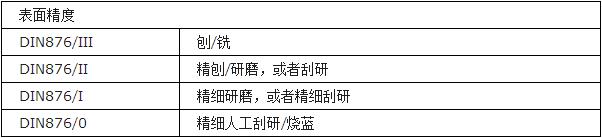

國外生產的鑄鐵平臺及國內外銷出口的平臺、使用國外設備的汽車鑄鐵平臺等產品常常會接觸到DIN標準,我公司長期為國外汽車試驗設備配套鑄鐵平臺產品, 將DIN標準的具體要求講述: DIN876設計 點在于測量表面的度,底部具備至少三個支撐點。鑄鐵平臺的設計將是例如允許作用在表面上的力朝著所述支撐點,以小化失真被引導的。

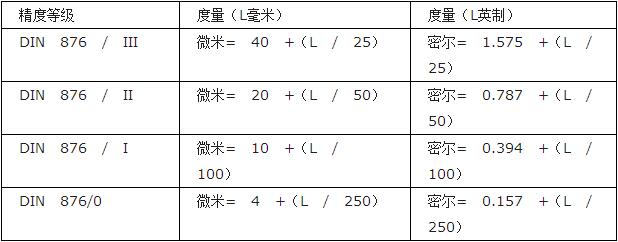

FLATNESS測(ce)(ce)量在(zai)20°C(68°F)標準溫度(du)。測(ce)(ce)量表面的(de)允許變化到(dao)的(de)平面以(yi)微米(μ)或密耳= 0.001英寸(cun),其中L是該板的(de)長邊的(de)長度(du)。

泊鑄DIN標準鑄鐵平臺加(jia)(jia)工工藝流程及設(she)備:一、鑄造(zao):采用(yong)樹(shu)脂砂消失模(mo),沖(chong)天(tian)爐熔煉(lian);結合實際情(qing)況取加(jia)(jia)工量(liang);制造(zao)鑄造(zao)工藝收縮率0.8,反變形(xing)量(liang)為3mm/m;模(mo)型——檢驗(yan)——造(zao)型——檢驗(yan)——烘干(gan)(gan)——合箱——澆注——測試——清理(li)——檢驗(yan)——鑄造(zao)毛(mao)坯成(cheng)型。所(suo)需設(she)備:4mX8m烘干(gan)(gan)窯、10T/n、15T/n、熔煉(lian)用(yong)沖(chong)天(tian)爐10T、5T、8T。鐵水包QI-2GAJF、碳硫聯(lian)合測定(ding)儀、100T拉力實驗(yan)機。一次(ci)去除內應(ying)力、時效溫度550度、所(suo)需設(she)備4mX8m退火窯。粗加(jia)(jia)工:劃(hua)線、粗加(jia)(jia)工留余(yu)量(liang)5mm。二次(ci)去除內應(ying)力與一次(ci)相同。加(jia)(jia)工:加(jia)(jia)工上下(xia)面,留余(yu)量(liang)0.2-0.3mm。并加(jia)(jia)工周邊四(si)面達到要求。后加(jia)(jia)工工作面,倒角。